Researchers at the Hefei Institutes of Physical Science of the Chinese Academy of Sciences have revealed the atomic-scale mechanism by which chromium enrichment improves the corrosion resistance of fuel cladding materials in lead-cooled fast reactors (LFRs).

Their findings were published in the Journal of Nuclear Materials.

Ferritic/martensitic (F/M) steels are considered leading candidates for LFR fuel cladding due to their mechanical properties and radiation resistance. However, these materials remain vulnerable to corrosion in high-temperature lead-bismuth eutectic (LBE) coolant environments. While controlling dissolved oxygen in LBE helps form protective oxide layers, enhancing the steel's intrinsic corrosion resistance continues to be a major challenge. Traditional experimental approaches are limited by their high cost and long testing durations, underscoring the need for mechanistically informed, predictive modeling tools.

To address this, the researchers conducted systematic research from two complementary perspectives: atomic-scale modeling and data-driven modeling.

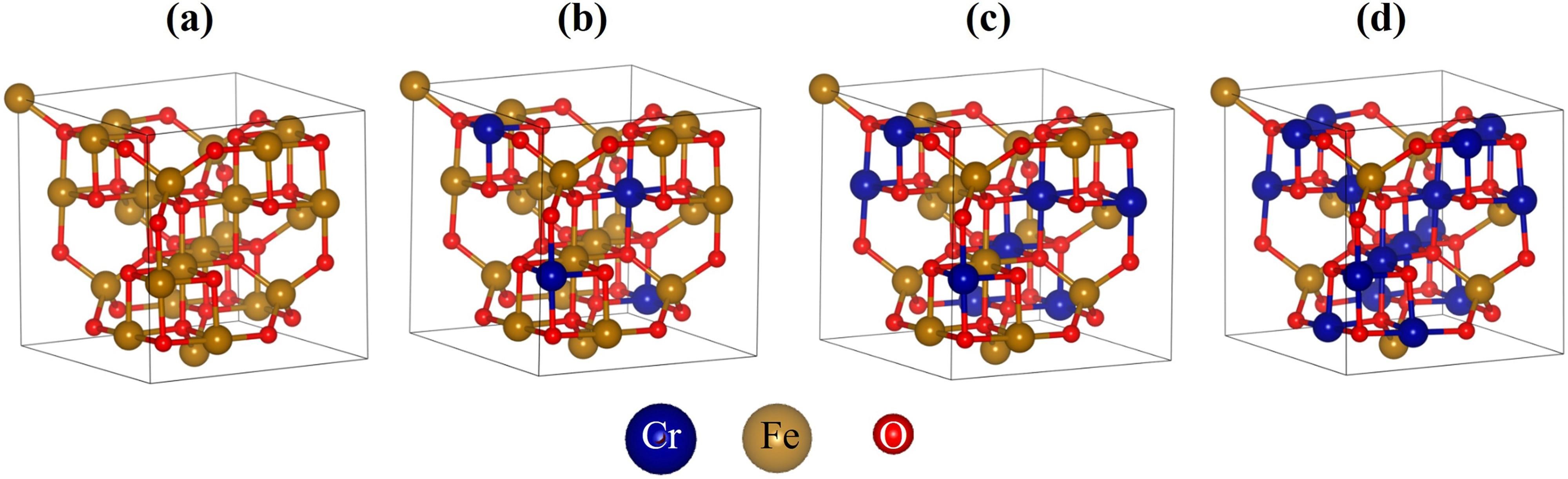

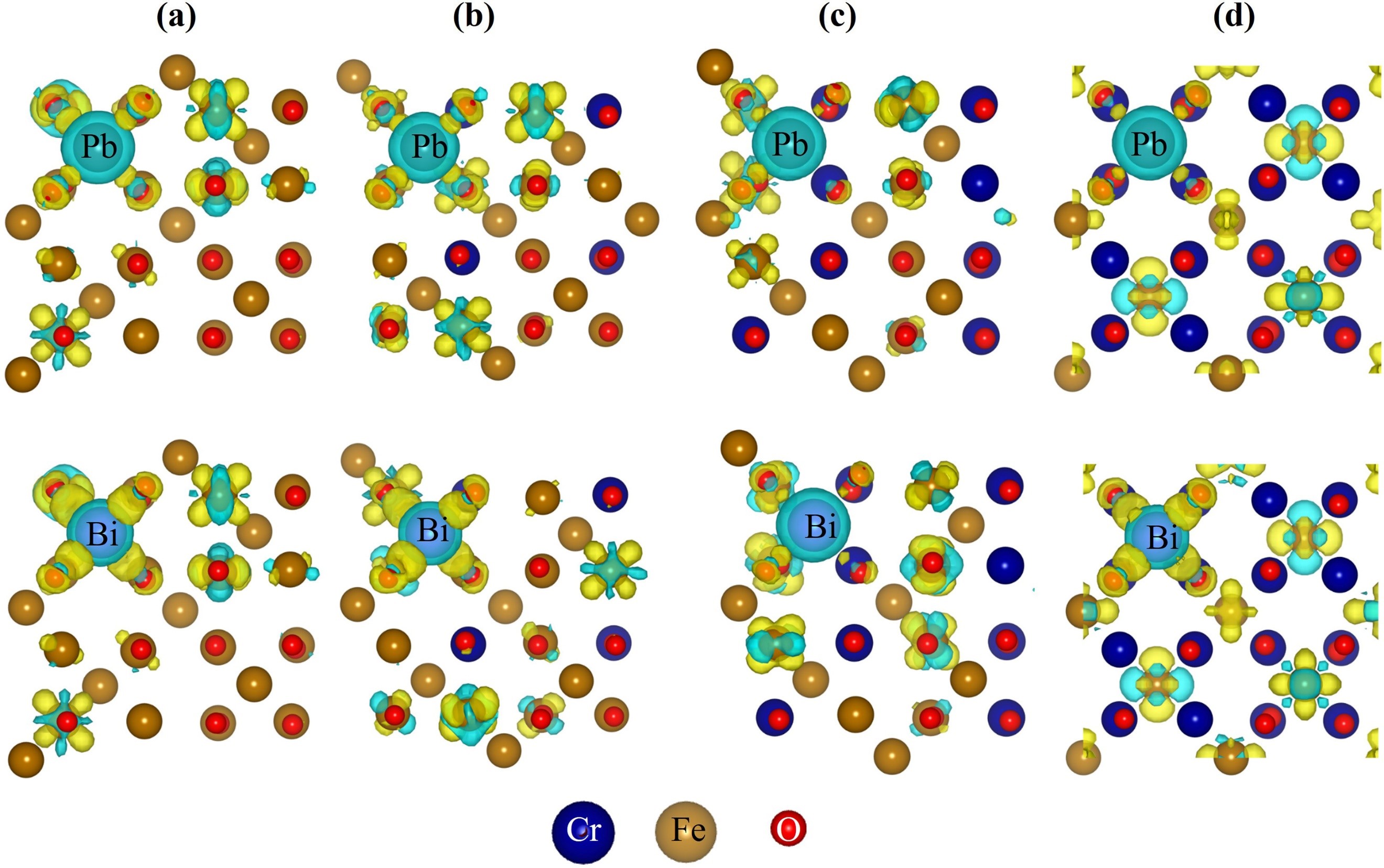

At the atomic scale, they employed density functional theory-based first-principles calculations to study the formation and migration of atomic vacancies in Fe₃₋ₓCrₓO₄ oxide layers with varying chromium content, as well as the effects of Pb and Bi. They found that chromium-enriched Fe-Cr spinel layers have higher vacancy formation energies and diffusion barriers than Fe₃O₄, impeding the diffusion of Fe, Cr, and O atoms.

These findings demonstrate how chromium enhances the stability of oxide layers, offering greater resistance to corrosion in LBE environments. This atomic-level insight provides valuable theoretical support for the design of high-performance, corrosion-resistant materials.

From a data-driven modeling perspective, the researchers developed an interpretable machine learning (ML) model to predict the oxidation corrosion behavior of F/M steels in static LBE conditions. By analyzing alloy compositions, test environments, and oxide scale thicknesses, they constructed a gradient boosting regression (GBR) model using nine key features. To ensure transparency and interpretability, they used the SHapley Additive exPlanations (SHAP) method to quantify the impact and nonlinear interactions of each feature.

This analysis revealed optimal concentration ranges for critical alloying elements such as Mo, Cr, and Si. Based on this, a multi-element synergy strategy was proposed to guide the design of oxidation-resistant alloys.

According to the researchers, these complementary modeling efforts offer both mechanistic insight and practical guidance, paving the way for more efficient development of advanced cladding materials suited for lead-cooled fast reactors.

Oxide structures of (a) Fe3O4, (b) Fe2.5Cr0.5O4, (c)Fe2CrO4, and (d)FeCr2O4. (Image by DENG Chengmin)

Charge density difference for Pb and Bi atoms in (a) Fe3O4, (b) Fe2.5Cr0.5O4, (c) Fe2CrO4, and (d) FeCr2O4. (Image by DENG Chengmin)

86-10-68597521 (day)

86-10-68597289 (night)

52 Sanlihe Rd., Xicheng District,

Beijing, China (100864)